Mechanical & Asset Integrity

Comprehensive Mechanical Integrity Solutions for Optimal Asset Performance

XCEL provides industry-leading mechanical integrity services as part of a turnkey program designed to enhance operational safety, reliability, and compliance. Our solutions integrate advanced technologies with unmatched expertise to meet the most stringent regulatory requirements.

Our Services …

Tailored Inspection Programs

We offer a fully customizable program for asset integrity management, using a comprehensive corrosion monitoring IDMS system that supports rule-based and risk-based (RBI) inspection programs. This allows us to proactively identify risks and extend the lifespan of your assets.

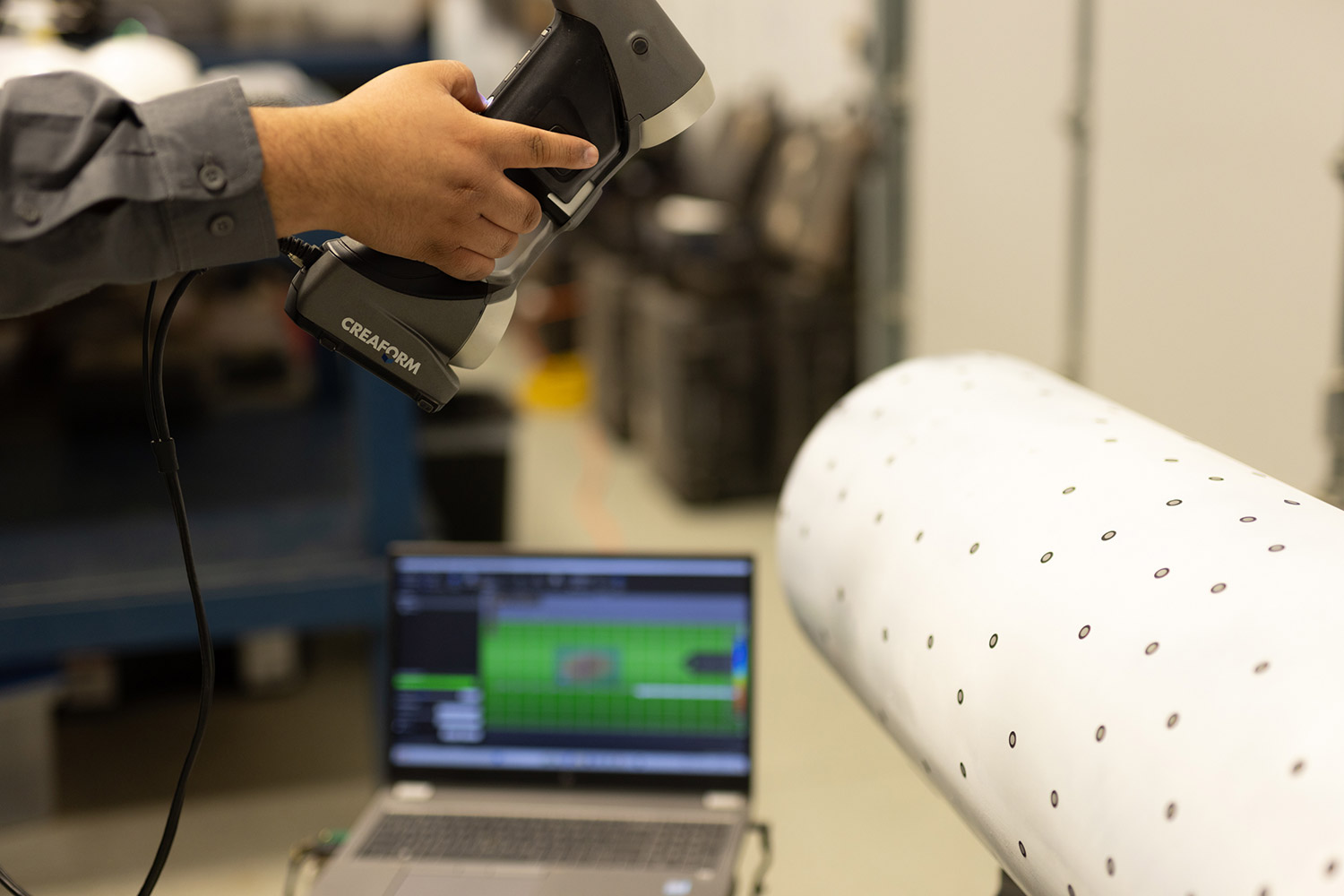

Expert Inspections and Data Acquisition

Our experienced API Certified Inspectors specialize in examining tanks, piping, and pressure vessels. With support from advanced NDT solutions, including UT shearwave, phased array ultrasonic testing (PAUT), and automated ultrasonic testing (AUT), we provide precise data to ensure your equipment meets safety and operational standards.

Regulatory-Driven Practices

Our services are fully aligned with OSHA’s Process Safety Management (PSM) standards, ensuring your pressurized systems comply with all mandatory safety requirements. This approach not only protects your assets but also reinforces sustainable and uninterrupted operations.

Comprehensive Record-Keeping and Analysis

We provide reliable data acquisition and meticulous record-keeping across all phases of inspection and monitoring. Using advanced tools like laser mapping, time of flight diffraction (TOFD), and digital radiography, our team supports precise performance tracking and compliance reporting.

Advanced Techniques, Tailored for Your Needs

- AUT Corrosion Mapping – Identify wall loss and create detailed topographic maps for pressure vessels, tanks, and pipelines.

- UT Thickness Testing – Monitor material thickness with precision to detect wear and ensure operational safety.

- Magnetic Particle Testing and Visual Inspections – Reliable techniques to assess surface integrity and detect critical flaws.

- Positive Material Identification – Verify materials to ensure fitness for purpose and compliance with standards.

- NDT Procedure Development and Auditing – Optimize in-house inspection processes with expert support from XCEL’s certified professionals.

Industries We Serve

Our mechanical integrity services cater to a diverse range of industries, including:

- Petrochemical – Comprehensive safety and compliance solutions for critical infrastructure.

- Power Generation – Tailored inspections for high-energy systems and critical components.

- Manufacturing – Ensuring the integrity of essential systems and equipment.

- Refineries and Pipelines – Specialized solutions including pipeline integrity inspections and pipe field services.

Why Choose XCEL for Mechanical Integrity?

- Comprehensive Expertise – Our team combines decades of experience across industries, from refinery inspections to infrastructure inspections, providing unmatched capabilities for both conventional and advanced NDT services.

- Cutting-Edge Technology – We utilize the latest inspection techniques, such as real-time radiography, guided wave ultrasonics, and entrapped water pH testing, ensuring precise analysis and actionable insights.

- Proactive Asset Management – Our mechanical integrity management solutions help reduce downtime and avoid costly repairs through proactive risk identification and mitigation.

- Regulatory Compliance Focus – Meeting industry standards is at the core of what we do. From coating inspections to pipeline monitoring, we ensure that your assets meet all applicable regulations.